[[ROW-INTRO]]Did you know that washing is an important step in denim production? This blog will explain what denim washing is, why it's important and how it can be done as sustainable as possible.[[ROW-INTRO-END]]

First things first - the denim washing we talk about here is not the same as the at-home washing you do to clean your jeans. The jeans you have at home are thrown into the washing machine whenever they get dirty. But did you know there is a different type of washing already happening before your new jeans arrive at your home?

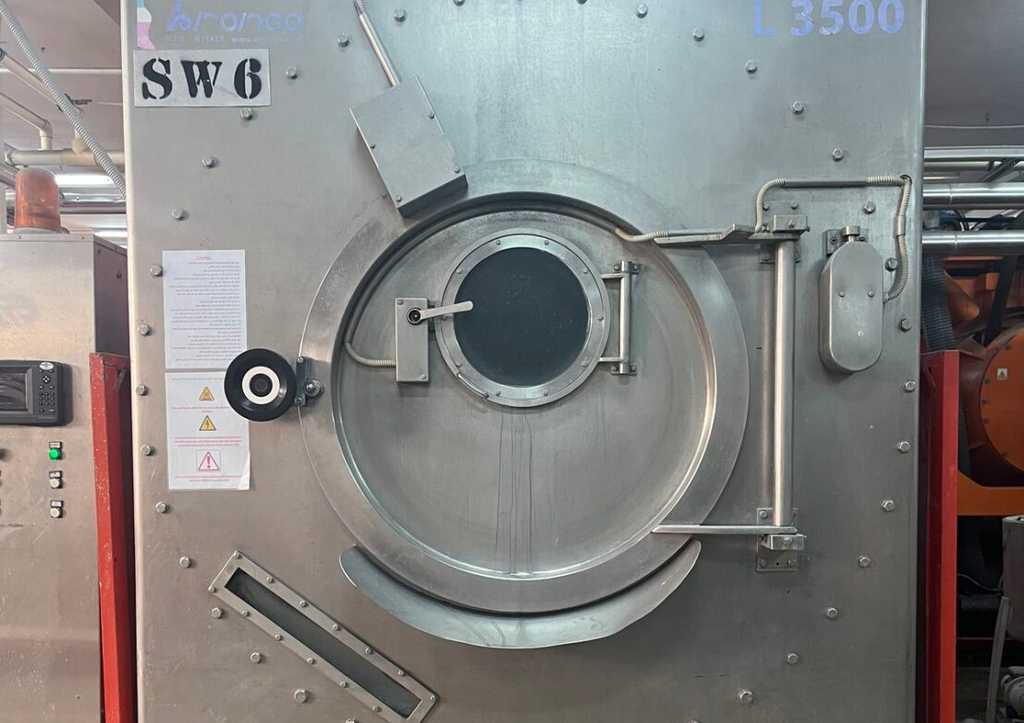

Denim washing is one of the very last steps involved in creating the final look of a jeans. Here, the jeans are also thrown into a (much larger) washing machine and washed to give jeans their classic worn out look, as in the image below. However instead of adding detergent, this type of washing process uses stones to achieve this look. The stones rub on the jeans, giving it different types of shading and texture.

Traditionally, the denim industry uses pumice stones for this process. These stones break down quickly (after only 1-1.5 washes) and soak up water, causing the pumice dust to combine with chemicals, indigo dye and fabric residue to create a so-called 'toxic sludge'. This sludge is harmful to the environment and also damaging to the machines and way of working at the factories. Beyond this, pumice stones also require factories to add more water to denim washes, to counteract the stones' water-attracting properties. For these reasons we choose to avoid the use of traditional pumice stones. Instead, we use an alternative type of stone created by HMS.

HMS was invented by an agricultural engineer who, after 30 years of experience in the denim industry, wanted to provide a better alternative to stone washing. The company creates stones made from upcycled pumice dust, an after product from pumice mines which they collect and reuse. This pumice dust is then bound by a ZDHC-certified (Zero Discharge of Hazardous Chemicals), organic binder. The result is a 50x more durable, hydrophobic (water-repelling) and circular stone wash alternative. This stone lasts up to 100 washes, while its hydrophobic properties also mean that it does not attract chemicals or residues and thereby does not create any toxic sludge. At the same time, they can significantly reduce transport-related carbon emissions, as at least 50x less stones are needed for the same amount of washes.

By looking at every step involved in the production of jeans, we aim to shed light on the fact that there is more to circularity and sustainability than the materials in the final product. With HMS, we are able to stone wash our jeans without the use of harmful pumice stones, using a circular alternative that avoids the creation of toxic sludge. Together MUD Jeans and HMS aim to shed light on the intricacies and innovative opportunities of circular production.

Kommentare

This article on washing denim

and sustainability is fantastic! It’s great to see how brands are making efforts to reduce their environmental impact while still delivering high-quality products.